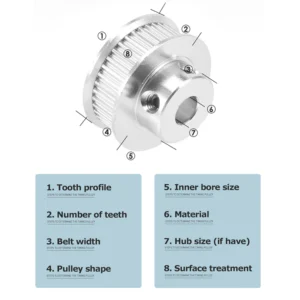

Teeth Profile: MXL, L, T5, T10, AT5, AT10, AT20, GT2, GT3, S4M, S5M, HTD8M, HTD14M – standard and custom timing pulley profiles supported

Number of Teeth: 10-150 teeth, custom tooth count available for OEM and custom timing pulley applications

Belt Width: 4mm to 50mm (metric & inch sizes supported), including 1/4″, 3/8″, 1/2″, 1″, up to 2″ – custom belt width available

Inner Bore: 2-200mm H7 precision bore, with optional keyway, set screw, bearing seat, shaft or taper bush

Material Options: Aluminum timing pulley, steel, stainless steel, brass, copper, POM, nylon – selected based on load, speed, and environment

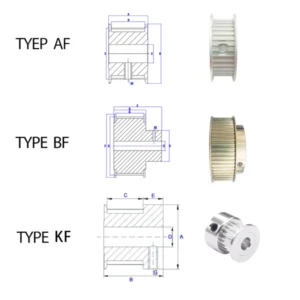

Product Shape: AF, BF, KF, AS, BS– standard and custom pulley structures available

Surface Treatment: Anodized, black oxide, phosphate, galvanized – suitable for various industrial environments

Color Options: Silver, black, blue, red, or customized

Accessories: Set screw, bearing, shaft assembly, taper lock bush available

Manufacturing Accuracy: CNC machined timing pulley with tolerance up to ±0.01 mm

(Example: “T25-AT5-Belt width 15mm-B10mm-Aluminium-Anodized-BF” = 25 teeth, AT5 teeth profile, belt width 15mm, 10mm bore, aluminium material, anodized surface treatment, BF shape.)

We specialize in manufacturing custom timing pulleys and OEM synchronous pulleys, CNC machined to ensure accurate tooth profiles, stable belt engagement, and long service life.

Production is available based on technical drawings, samples, or detailed specifications.

Our timing pulleys are designed for applications requiring precise motion control, consistent torque transmission, and low backlash.

We support a wide range of standard and custom tooth profiles to meet different industrial requirements:

Trapezoidal: MXL, XL, L, H, XH, XXH

T Series: T5, T10, T20

HTD / Arc Tooth: HTD3M, HTD5M, HTD8M, HTD14M, GT2, GT3

S Series: S2M, S3M, S4M, S5M, S8M

Other Profiles: AT series, parabolic and special profiles on request

Custom tooth profiles can be manufactured according to drawings.

Material selection is based on load, speed, environment, and application requirements:

Aluminum timing pulley: Lightweight, corrosion-resistant, ideal for automation and robotics

Steel timing pulley: High strength for heavy-duty and high-torque applications

Stainless steel: Excellent corrosion resistance for harsh environments

Brass / Copper: Low friction, wear-resistant, special electrical or thermal needs

POM / Nylon: Low noise, lightweight, suitable for automation and laboratory equipment

Key Manufacturing Features

High Precision: CNC machining with dimensional tolerance up to ±0.01 mm

Stable Transmission: Accurate tooth pitch ensures non-slip synchronous operation

Low Noise & Low Runout: High concentricity of bore and outer diameter

Smooth Finish: Burr-free edges and precision bore for easy installation

No Lubrication Required: Low maintenance during operation

OEM & Customization Capabilities

We provide OEM/ODM timing pulley solutions with:

Manufacturing strictly according to drawings or specifications

Custom bore sizes, keyways, flanges, and surface treatments

H7 bore tolerance and concentricity within 0.05 mm

Engineering drawing confirmation within 24 hours

Our custom timing pulleys are widely used in:

CNC machines and automation equipment

Industrial robotics and packaging systems

3D printers and precision motion systems

Automotive and OEM mechanical equipment

Laboratory automation and imaging systems

Professional shockproof packaging for safe transportation

Stable supply and export-ready logistics

Support for international OEM orders

Send us your drawing or technical requirements.

Our engineers will review your specifications and provide a manufacturable solution within 24 hours.

Welcome to Yongchenghui, your trusted partner in precision mechanical components and automation solutions.

Building 26, Lianmei 1st Road, Shangcun Community, Gongming Street, Guangming District, Shenzhen, Guangdong,China

© 2025 Yongchenghuifa, All Rights Reserved

Building 26, Lianmei 1st Road, Shangcun Community, Gongming Street, Guangming District, Shenzhen, Guangdong,China