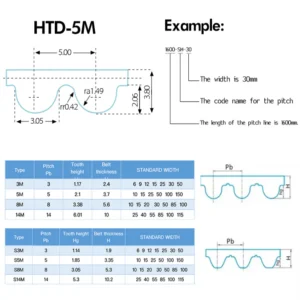

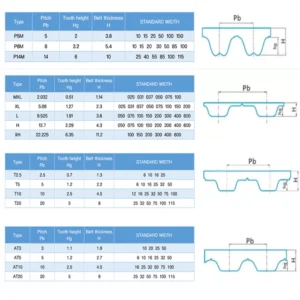

Tooth Profile: MXL, L, T5, T10, AT5, GT2, GT3, S4M, S5M, 8M, 14M, as requested

Number of Teeth: 10-150 teeth or customized

Belt Length: 500-3200mm, as requested

Belt Width: 6mm, 10mm, 15mm20mm, 25mm, 30mm, 40mm, 50mm, 1/4”, 5/16”, 3/8”, 1/2”, 3/4”, 1”, 1.5”, 2”or customized

Material Available: Polyurethane, Rubber, Nylon, PVC, Reinforced Fiberglass

Product Types: Open-ended, Endless, Double-sided, Thicker belt, Green fabric reinforcement

Color Available: White, Black, Green, Red, as requested

Features: Precise synchronization, smooth engagement minimizes noise,temperature resistant.

(Example: “639mm-3M-Belt width 15mm-Polyurethane” = 639mm length, 3M teeth profile, belt width 15mm, polyurethane material.)

Timing belt is a type of mechanical belt that features teeth on its inner surface, designed to engage with the teeth of timing pulleys. It is used to transfer rotational motion between shafts while ensuring precise synchronization of movement. Unlike standard belts, timing belts minimize slippage, making them ideal for applications requiring accurate timing and positioning.

Various Tooth Profiles Available:

Materials:

Types:

Key Features:

Simple Structure:

Easy to install, easy to assemble and disassemble.

Application Scope:

Widely used in automotive industry, industrial machinery such as conveyor systems, packaging machines, and textile machinery. Robotics, integral to robotic systems, providing accurate movement control and synchronization of different robotic components.

Logistics service advantages:

Welcome to Yongchenghui, your trusted partner in precision mechanical components and automation solutions.

Building 26, Lianmei 1st Road, Shangcun Community, Gongming Street, Guangming District, Shenzhen, Guangdong,China

© 2025 Yongchenghuifa, All Rights Reserved

Building 26, Lianmei 1st Road, Shangcun Community, Gongming Street, Guangming District, Shenzhen, Guangdong,China