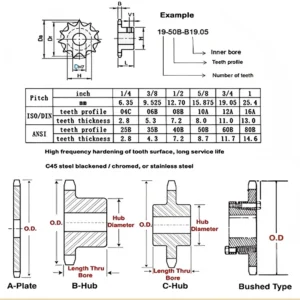

Number of Teeth (Z): 10-120 teeth, as requested

Pitch(P): 1/4’’,3/8’’, 1/2’’, 5/8’’, 3/4’’, 1’’, as requested

Teeth Profile: 04C, 25B, 06B, 35B, 08B, 40B, 50B, 10A, 12A, 16A, as requested

Bore Size: 5mm,10mm,15mm,20mm,30mm,40mm,1/4”, 5/16”, 1/2”, 3/4”, 1”, 1.5”, or customized

Chain Standard: ANSI (USA), DIN/ISO (Europe)

Material Available: Steel, stainless steel, POM

Surface Treatment: Blackened, Chromed, Galvanized(zinc plating), Nickel plating, As requested

Sprocket Type: Plate, Idler, QD, Tapered bushing, Split, Double-row, Finished bore, Plate bore, As requested

Features: High load capacity and durability. Good wear – resistance.

(Example: “T19-50B-B19.05-Steel-Blackened” = 19 teeth, 50B teeth profile, 19.05mm bore, steel material, blackened surface treatment.)

Sprocket, also known as a chain wheel, is a mechanical component designed to mesh with a chain. It typically features a series of evenly spaced teeth around its circumference. These teeth engage with the links or rollers of the chain to facilitate the transmission of power and motion between different parts of a mechanical system.

Types:

Materials:

Surface Treatment:

Key Features:

Heat Treatment:

Simple Structure:

Easy to install, easy to assemble and disassemble. They can be easily mounted on shafts or hubs using appropriate fasteners.

Application Scope:

Sprockets are widely used in various mechanical applications. Such as industrial machinery, conveyor systems, automotive industry,material handling systems, robotics, packaging machinery,food processing equipment an so many other heavy machinery.

Logistics service advantages:

Welcome to Yongchenghui, your trusted partner in precision mechanical components and automation solutions.

Building 26, Lianmei 1st Road, Shangcun Community, Gongming Street, Guangming District, Shenzhen, Guangdong,China

© 2025 Yongchenghuifa, All Rights Reserved

Building 26, Lianmei 1st Road, Shangcun Community, Gongming Street, Guangming District, Shenzhen, Guangdong,China