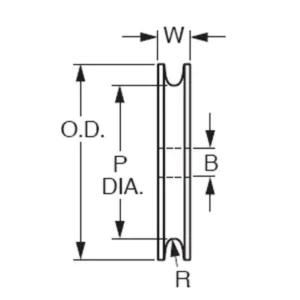

Groove Type: V-groove pulley, H-groove pulley, U-groove pulley,Toothed groove, etc.

Bore Size: 5mm,10mm,15mm,20mm,30mm,40mm,50mm,1/4”, 5/16”, 1/2”, 3/4”, 1”, 1.5”, or customized

Number of Grooves: Single or multi-groove for power needs

Bearing Type: 608ZZ, 625ZZ or as requested

Outer Diameter (OD): 20mm-150mm, as requested

Pulley Width: 5mm-40mm, as requested

Material Available: Aluminum, Steel, Stainless steel, Nylon

Flange Design: Flangeless, Single-flange, or double-flange for belt tracking.

Features: Smooth operation ensures that the force applied is efficiently transferred to the object being moved or lifted, improving the overall mechanical efficiency of the system.

(Example: “OD 55mm*Width 40mm-U groove-R14.25- Groove depth 14.25mm*width 28.5mm-B14mm- Steel)

Pulley is a grooved wheel on an axle, used to redirect rope/cable tension, providing mechanical advantage to reduce lifting force. It can be single for force redirection or in systems (block and tackle) to multiply efficiency, fundamental in construction for heavy lifting and machinery for power transmission via rotational mechanics.

Various Groove Types Available:

Materials:

Key Features:

Support Customization:

Simple Structure:

Easy to install, easy to assemble and disassemble.

Application Scope:

Pulleys are widely applied to lift, move loads, or transmit power. In construction, cranes use them to hoist heavy materials via pulley systems for mechanical advantage. Industrial conveyor belts rely on pulleys to drive continuous material transport in factories. Automotive engines use drive pulleys for accessories like alternators. Fitness equipment employs pulleys in cable machines for resistance adjustment. Elevators use large pulleys with counterweights for smooth vertical movement, while they also function in sailing for sail control and window blinds for easy operation.

Logistics service advantages:

Welcome to Yongchenghui, your trusted partner in precision mechanical components and automation solutions.

Building 26, Lianmei 1st Road, Shangcun Community, Gongming Street, Guangming District, Shenzhen, Guangdong,China

© 2025 Yongchenghuifa, All Rights Reserved

Building 26, Lianmei 1st Road, Shangcun Community, Gongming Street, Guangming District, Shenzhen, Guangdong,China