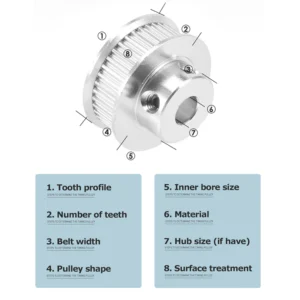

Teeth Profile: MXL, L, T5, T10, GT2, GT3, S4M, S5M, HTD8M, HTD14M, as requested

Number of Teeth: 10-150 teeth or customized

Belt Width: 4mm,6mm,10mm,12mm,15mm,20mm,25mm,30mm,40mm,50mm, 1/4”, 5/16”, 3/8”, 1/2”, 3/4”, 1”, 1.5”, 2”or customized

Inner Bore: 2-200mm H7 precision or customized

Material Available: Aluminum, Steel, Stainless steel, Brass, Copper, POM, Nylon

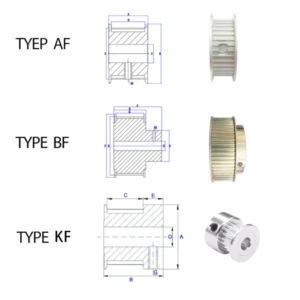

Product Shape: AF, BF, KF, AS, BS, as requested

Surface treatment Available: Anodize, Black Oxide, Phosphate, Galvanization

Color Available: Silver, Black, Blue, Red, as requested

Accessories: Set screw, Bearing, Shaft or Taper bush

Features: Accurately match the demand and improve the efficiency of the system.

Special customized timing pulleys are non-standard transmission components designed to meet the special working conditions that standard timing pulleys cannot achieve. Their core feature is high personalization, covering customization in multiple dimensions such as geometry, material, tooth profile, and integration.

Various Teeth Profiles Available:

Materials:

Key Features:

Support Customization:

Simple Structure:

Easy to install, easy to assemble and disassemble.

Application Scope:

Special custom timing pulleys are designed for unique industrial and mechanical applications where standard pulleys cannot meet performance, space, or environmental requirements. Widely used in Industrial automation & robotics, medical & laboratory equipment, automotive & electric vehicles and so on.

Logistics service advantages:

Welcome to Yongchenghui, your trusted partner in precision mechanical components and automation solutions.

Building 26, Lianmei 1st Road, Shangcun Community, Gongming Street, Guangming District, Shenzhen, Guangdong,China

© 2025 Yongchenghuifa, All Rights Reserved

Building 26, Lianmei 1st Road, Shangcun Community, Gongming Street, Guangming District, Shenzhen, Guangdong,China