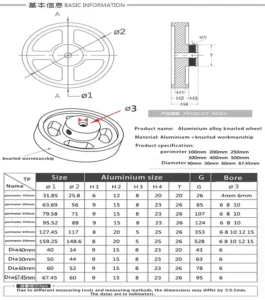

Outer Diameter (OD): 30mm,40mm, 50mm, 60mm, 68mm

Perimeter: 100mm, 200mm, 250mm, 300mm, 400mm, 500mm

Width: 22.6mm, 23mm, 28mm, 25mm, 27mm

Bore Size: 4mm,5mm, 6mm, 8mm, 10mm, 12mm, 15mm

Hardness: Shore 65A

Material: Polyurethane, aluminium

Metal core: Aluminium

Rubber thickness: 10mm, 12mm, 13mm

Color Available: Natural color

Load Capacity: Max 300KG

Features: High Temperature Resistance.

(Example: “Perimeter 100mm-B6mm-Polyurethane” = Perimeter 100mm, Bore 6mm, polyurethane material.)

Encoder wheels (also called code wheels or encoder disks) are precision mechanical component that converts rotational motion into digital electrical signals for position, speed, or direction feedback. Typically equipped with evenly spaced teeth or slots, it works with a sensor to generate pulse signals (PPR: Pulses Per Revolution), enabling precise measurement of rotational displacement. Made from durable materials like aluminum alloy or polyurethane, it features anti-interference design (e.g., IP protection) and can withstand harsh environments, widely used in industrial automation, robotics, and motion control systems.

Materials Available:

Metal Core Available:

Hardness:

Range 65A shore. Standard hardness for encoder wheel.

Key Features:

Simple Structure:

Easy to install, easy to assemble and disassemble.

Application Scope:

Encoder wheels are critical components in motion control systems, converting mechanical rotation into precise digital signals. Their key applications include: industrial automation, consumer electronics, energy sector, automotive & transportation.

Logistics service advantages:

Welcome to Yongchenghui, your trusted partner in precision mechanical components and automation solutions.

Building 26, Lianmei 1st Road, Shangcun Community, Gongming Street, Guangming District, Shenzhen, Guangdong,China

© 2025 Yongchenghuifa, All Rights Reserved

Building 26, Lianmei 1st Road, Shangcun Community, Gongming Street, Guangming District, Shenzhen, Guangdong,China